How $200M–$2B Retailers Are Reclaiming Margin

Sponsored by Rockhill America

A merchant’s week used to be about choosing from what wholesalers had ready. Today, it’s about shaping the line—refreshing finishes, right‑sizing packs, extending winning forms into adjacent price points—and doing it in weeks, not seasons. The gap between those two realities is where margin erodes. Distributors are efficient at “good enough,” but their middle takes a toll and slows iteration. Full in‑house importing, on the other hand, demands a specialized team: sourcing managers, engineers, compliance, QC, logistics, country‑of‑origin planning, vendor scorecards—the list is long, and the recruiting cycle is longer.

Networked direct sourcing bridges the gap. Retailers brief directly to factories through a partner that already has the supplier network, the consolidation muscle, and the Asia‑based execution layer. That’s how you get the “best of both worlds”: low or flexible MOQs to test and scale, plus factory economics to rebuild gross margin. In practice it looks like this: a curated base of developed items across home décor, mirrors, lighting, planters, faux florals, storage boxes, handicraft, small furniture, and now pets; a digital portal to explore the range and issue briefs; structured sampling with factory engineers; and mixed‑factory, mixed‑category loads that land efficiently.

Tariffs, while unavoidable, become variables you can manage rather than fate. With development capability and vetted capacity in Vietnam and China, retailers can plan country of origin at the SKU or material level, shift selectively, and preserve design intent while keeping the cost profile in range. That dispersion of risk—by factory, by material, by country—matters as much as the first‑cost on any given item.

The KPIs tell the story. When merchants can brief on Monday and see meaningful movement by the next line review, time‑to‑shelf shrinks. When you mix factories and categories into consolidated containers, freight per unit becomes predictable. When MOQs bend to a retailer’s test‑and‑learn cadence, the assortment breathes: you can incubate newness without betting the farm, then scale what works. In store, the payoff shows up as SKU productivity per square foot (or square meter)—not only because margins are tighter at the item level, but because freshness lifts traffic, and adjacencies convert.

Consider an illustrative example. A regional chain at roughly $500 million wants to go harder at wall and accent lighting without bloating inventory. They pilot 60 SKUs across mirrors, decorative lighting, and planters using flexible MOQs. They consolidate loads from two factories in Vietnam and one in China to optimize freight. After two cycles, they retire 20 SKUs, double down on 15 clear winners that beat margin targets, and open a pets end‑cap that extends their brand into a fast‑growing adjacency. Not a silver bullet, not a moonshot—just systematic, measurable progress.

For many teams, the technology layer is what unlocks the behavior change. A clean portal—one that reflects real factory capabilities, current mold libraries, finish options, pack specs, and compliance status—shortens every conversation. Merchants and planners spend less time chasing PDFs and more time shaping assortments. Packaging, labeling, and social compliance move in lockstep because they’re baked into the same workflow as engineering and sampling. And because consolidation is designed from the start, not bolted on at the end, you avoid the last‑mile scramble that quietly taxes margin.

All of this is, of course, still about people. It’s about giving lean merchant teams the leverage of an import office without the overhead, and giving factories clear briefs, steady demand, and predictable consolidation so they can price sharply and deliver cleanly.

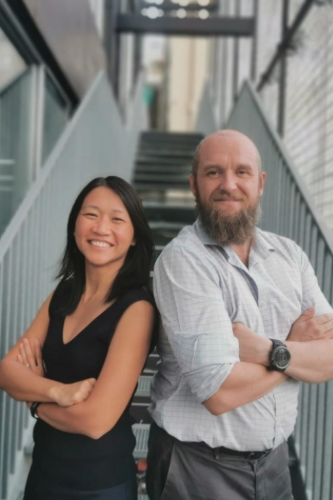

That people‑first premise is what led Claude Rety and Fiona Li to found Rockhill America and its sister company Rockhill Asia. As CEO and COO, respectively, they built the model around the retailer who has the scale to benefit from direct sourcing but not the appetite to stand up an entire import organization.

“Retailers shouldn’t have to choose between a high‑overhead import team and a margin‑eroding distributor model,” says Rety. “We designed Rockhill to deliver the best of both—flexible MOQs with true factory access—so merchants can move quickly and still see line‑of‑sight to landed cost.”

Li underscores the cadence: “Our teams in Vietnam and China work hand‑in‑hand with factories. When a merchant issues a brief, engineering, sampling, and compliance are already coordinated at origin. That’s how you make the next line review count.”

The categories where this approach tends to sing are the ones where material nuance and finishing flexibility matter: carved or cast décor, metal and mixed‑material mirrors, small occasional pieces, woven planters and baskets, textured storage solutions, faux florals with tight color direction, and lighting where scale, diffusion, and finish have to hit a value sweet spot. Pets—collars, beds, storage, feeding—has become an especially productive adjacency for chains looking to widen the basket. The common thread is the need to test quickly, hold MOQs in check, and extend winning silhouettes across finishes and price points without reinventing the wheel each time.

If you’re evaluating partners, the questions are straightforward—even if the answers aren’t. How do they keep MOQs flexible without back‑loading cost? How deep is their factory bench by material and country? Who actually owns QC and social compliance at origin? What does the consolidation network look like, port to port? How do your merchants brief and iterate—portal only, PLM integrations, both? And most of all: what’s the test‑and‑scale cadence you can expect over the first two seasons?

The retailers already on this path tend to start focused—one or two departments, a clear gross‑margin target, a defined store set—and expand once the loop proves itself. They use the early cycles to validate that the assortment changes the conversation on the salesfloor, that the freight math works in real life, and that the compliance documentation flows without friction. From there, they widen the lane: more SKUs, more adjacencies, more of the store speaking the same value language.

The opportunity isn’t to make importing glamorous; it’s to make it invisible. When direct‑to‑factory development, flexible MOQs, and country‑of‑origin planning operate as a single system, merchants regain time, planners regain confidence, and the customer sees something simple: better product at a better price, refreshed more often.

Rockhill America, founded by CEO Claude Rety and COO Fiona Li, helps $200M–$2B+ retailers launch and scale direct‑to‑factory programs without building an in‑house import team. In partnership with Rockhill Asia—with teams in Vietnam and China—Rockhill combines flexible MOQs, a vetted factory network, consolidation logistics, and a digital product portal across décor, mirrors, lighting, planters, faux florals, storage boxes, handicraft, small furniture, and emerging categories like pets.

Take the next step toward better margins and faster assortments. Email info@rockhillasia.com. Follow us on LinkedIn.