June 11-12 event at the Hickory Metro Convention Center showcases products, materials and services from more than 100 exhibitors

HICKORY, N.C. — Seeking to bolster business opportunities with residential and commercial furniture manufacturers, industry suppliers attending this year’s Furniture Manufacturing Expo generated mostly positive reviews for the event despite lingering concerns ranging from soft retail traffic to the uncertainties posed by tariffs.

Exhibitors offered a wide mix of products and services ranging from hardware and nail-head trim to sewing machines and large-scale fabric- and leather-cutting equipment, to name several core categories. It also was an opportunity for companies to showcase innovations, some of which have been in the works for several years or more.

A case in point was the vertical hanging spray finish system developed by Nathan Guffey of Guffey Systems about seven years ago. Created as a modular system that can be scaled to the finishing needs of the manufacturer, it is designed for all sides of a wood panel to be finished at once, as opposed to finishing one side of a panel at a time on a horizontal pallet.

Having primarily sold the system to cabinet producers, this was the company’s first time showing to the furniture sector, noted Kenny Guffey, who handles sales for the company.

“You can spray all sides at once and you can do all your scruff sanding here as well,” Guffey said of the domestically manufactured system, adding, “It’s totally scalable and it has as much of a materials handling benefit as it does spraying.”

Hanes Industries, a division of Leggett & Platt, reported a mostly positive show experience.

“We’re very pleased with the traffic that has been through the show,” said Tim Allen, market manager at Hanes Industries. “We’ve had meaningful conversations with a number of key customers. … We are pleased with the folks we have seen.”

He said that one of the products it was featuring at the event was a stiffened fabric meant to replace cardboard on the outside and inside arms of upholstery.

“We are always working on different innovations in the construction of the fabrics we provide,” he said, noting that most of these and other types of fabrics come from overseas, “because of the way the textile industry has evolved over the last 20 years.”

Beeson Industrial of High Point has a line of some 30,000 products ranging from adhesives and abrasives to packaging equipment. It also showcases a line of plywood, MDF, particle board and pressure-treated lumber.

At the show, it was highlighting its made-in-Brazil hardwood/plywood products, featuring 13-ply, 22mm construction, which it showed next to the product of some competitors in the marketplace featuring 7-ply, 8mm construction.

“We sell to all the major furniture manufacturers,” said Mark Miller, senior account manager. “You name it, we’ve got it.”

Miller said Beeson has been showing at the the event for the past few years and that it has been good for the company.

“If we pick up two to three good customers, it is worth us showing,” he said, noting that customers shopping the event continue to seek the best materials at the best prices, particularly amid a global supply chain impacted by tariffs, including steel and aluminum tariffs of 50% from around the world.

“Everybody is looking for the best value they can get,” he said, noting that while prices of metal products such as screws have not gone up yet, “we know it’s a matter of 30-60 days before we get hit.”

Other companies also were sensitive to the tariff situation, whether on metal or other products, including those coming from China.

Allen, of Hanes Industries, noted that while the company sources from many different parts of the world, the majority of its products have shifted outside China, which helps it avoid high tariff levels compared to other countries.

“It’s business as usual in terms of long-term business planning,” he added, noting that the industry looks forward to understanding what the end result will be “so we can make our plans accordingly.”

Heico, a producer of metal screws, connectors, brackets, tack strips, panel nails, decorative nail-head trim and more, said it was having a strong show, with attendance from many different areas outside North Carolina, including Michigan, Minnesota and California, to name a few.

It’s been a strong year for the company so far, as business has been up from last year, noted Wen Watts, North American sales manager. But with 90% of its core product made with steel, the company is keeping an eye on tariffs.

“My core product is made in Germany,” Watts said, noting that the company also does some metal stamping in its U.S. facilities that also use American steel. “But my core product, decorative nails, which has been our core product forever, the steel comes out of Germany. And of course we do import some parts out of China and other countries, too.”

A big question now for the company and others is where China and other country tariffs will end up as the U.S. continues to negotiate the final rates in the coming weeks.

“We are concerned about it, but it is a wait and see,” said Jean-Simon Pageau Dufresne, furniture sales manager of industry hardware specialist Richelieu, of Montreal. It manufactures its product in Canada and has offices in Thomasville, North Carolina, and about 130 warehouse locations in North America, spread between the U.S. and Canada.

Some companies that manufacture metal and other components in the U.S. touted their domestic capacity as an advantage, particularly relating to service and speed to market, not to mention the avoidance of tariffs.

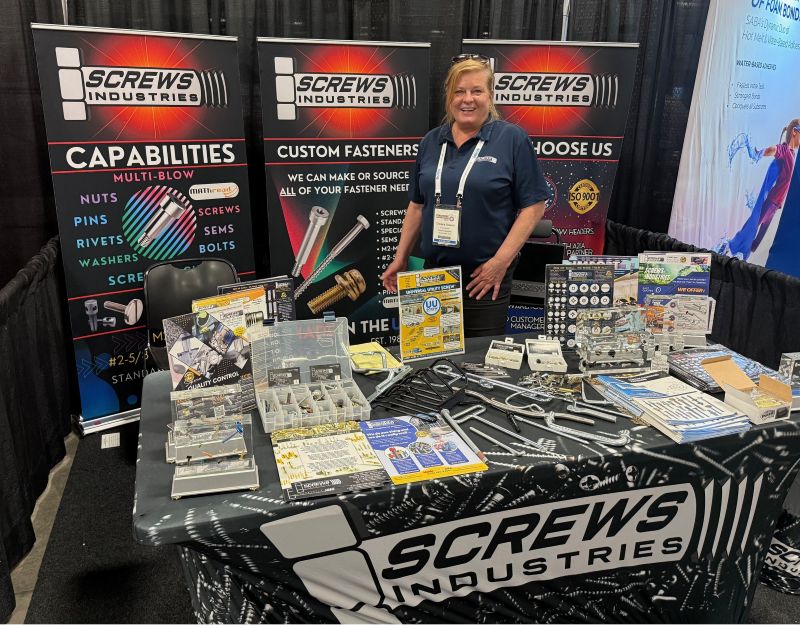

For example, Screws Industries of Glendale Heights, Illinois, was showcasing a wide mix of products in its line, which ranges from screws and bolts to washers and rivets, to name several. Its product is 100% made domestically, said Charlene Roberts, a company sales professional.

“We’re beating prices from Taiwan and China with the 50% tariff,” Roberts said, noting that several well-known manufacturers stopped by the space at the show. “Right now they are looking for those domestic parts.”

C.S. Osborne & Co., of Harrison, New Jersey, was showing key aspects of its line made in New Jersey and Massachusetts, such as decorative nail trim and tack strip and flex strip materials.

“The majority of our business is to the residential furniture industry,” said Jake Angell, president of the company, which is celebrating its 199th-year anniversary this year.

He added that, while the company produces some products such as sewing needles in Germany, the majority of its line is domestically made, which is of keen interest to the industry because of the price increases many manufacturers have seen relating to tariffs.

“We are more competitively positioned,” he said, adding that some of the items in its line can’t be found elsewhere as “only Osborne makes them.”

Card Clothing & Services Inc., of Huntley, Illinois, manufactures material preparation and filling systems for the furniture, bedding and automotive industries, as well as for filtration and pet products. It manufactures in Illinois and has a sales and service center in Kings Mountain, North Carolina.

While it doesn’t write orders for its large-scale equipment at the show, it’s still a good way to connect with customers in the residential furniture and bedding segments, noted Scott Webb, head of sales and marketing.

“We have had very good business on the bedding side,” he said, adding that while it’s been a little soft, “furniture is still very good for us.”

Webb also noted that the company tries to buy all U.S. parts for its equipment, thus lowering any impact from tariffs. While there has been some cost pressure related to materials, he said that the company is trying to keep any price increases to a minimum.

Home News Now also ran into a number of industry contacts from companies including Bassett, Chromcraft and Stone & Leigh, to name a few.

Jay Foscue, president and chief operating officer of Stone & Leigh, said that service remains a key consideration in buying decisions, perhaps even more than where it’s made.

“Where it comes from will sort itself out in the end,” he said, a reference to global sourcing ultimately impacted by the tariff situation.

Alan Kerley, director of upholstery operations at Bassett Furniture, said he and his team came to the show to shop the best and best-priced product in packaging materials and hardwood plywood, while also checking out anything else that’s “new and the latest and the greatest” in materials for the furniture industry.

“It’s informative,” he said of the show, which he said the company has been coming to for many years. “There is a lot of stuff that we will never use, but it’s nice to know what’s out there.

“You don’t want to skimp for sure,” he added of anything the company decides to shop and purchase. “Customers don’t deserve that.”